Water Treatment System Q&A

|

| Wastewater Treatment FAQ |

Q1.Necessity of wastewater treatment

Even when the wastewater appears to be clear, the wastewater cannot be

discharged unless it satisfies applicable water quality standards. In other

words, as long as it satisfies the standards, the wastewater can be discharged

even when it is not clear.

(Water containing COD of 20,000mg/L [20,000ppm/L] exists although the

water appears to be clear.)

|

|

Q2.What are the cost of treating industrial water and sewage?

If water intake is 20t/day and the same amount is discharged, the total

cost, including the fees for industrial water and treatment of sewage,

will accumulate to huge amounts over a period of five years as shown in

the chart below. For example, if wastewater from the factory is purified

and 85% of it is refused, conservation of water leads to a substantial

savings in costs.

Investing in a wastewater purification system and conserving water can

reduce much more cost than diluting and discharging wastewater from the

factory.

|

|

|

Q3.What are effluent standards?

1) Typical water quality criteria:

(pH)Acidity, Alkalinity:

The pH of 7 is considered to be neutral. As the number decreases (pH6,

5, 4), the acidity increases. Similarly, the alkalinity increases as the

number increases (pH8, 9, 10).

Increment pH by 1 implies 10 times more change in the concentration. For

instance, pH10 is 1,000 times of pH7, and pH12 is 100,000 times more.

(SS)Turbidity:

Total of solids (e.g. organic substances), depth of color, and cloudiness

is quantified.

(BOD)Biochemical Oxygen Demand:

The smaller the value is, the less oxygen is consumed, and biodegradation

is more easily done.

The amount of oxygen used to decompose contaminants by bacteria is measured

and quantified.

(COD) Chemical Oxygen Demand:

The mixture level of chemical components

Instead of bacteria, contaminants are decomposed using chemicals (oxidant)

and the contaminant level is indirectly measured and quantified.

(T-N)Total nitrogen:

Sum of nitrate, nitrite, ammonium nitrogen, and etc is quantified.

(T-P)Total phosphorus:

Sum of phosphorus components is quantified.

※1 Neutral pH is the standard for these standard values. The smaller SS,

BOD, COD, T-N, and T-P values are, more environmental contamination is

prevented. The larger values indicate that it would be more likely to trigger

eutrophication of lakes and ponds, and contamination of ground water, affecting

our living environment.

※2 Effluent standards become stricter year by year. In addition to the

Water Pollution Control Act, some local governments set own regulations

(e.g. pH 5.8 to 8.6,SS 70,BOD 70ppm,COD 40ppm,Nitrogen 60mg/L,Phosphorus

8mg/L). (Effluent standards vary, depending on local regulations.)

※3 Effluent standards for sewage effluent is the strictest, then river,

and ocean. However, there are no clear regulation values for spraying livestock/dairy

liquid fertilizer.

|

|

Q4.Necessity of water purification test

Necessity of the purification lab test:

Purification lab test is conducted for the samples from each site. Water

purification is verified by the certification of the concentration measurement.

Wastewater samples do not show the same condition as they vary depending

on components including chemicals, concentrations, meteorological environment,

bacterial responses, and electric conductivity. Therefore, the purification

lab test (with charge) is required even when the wastewater is produced

in the same industry and has the same name.

The test is also essential to determine the guarantee values for the water

quality when a new system is installed.

Purification lab test procedure:

Provide us four liters of actual wastewater for the test. We will review

the sample and determine an appropriate purification method.

Before and after the purification, the water quality is analyzed and compared

through beaker tests in order to verify the effect of the purification.

We will provide optimal quotations to meet your needs.

Rust-colored water electrolysis wastewater treatment (View Video) Rust-colored water electrolysis wastewater treatment (View Video)

|

|

Q5.Judging results of the purification test

When the results of the purification lab tests satisfy the standards of

the local water effluent regulations, the wastewater can be discharged

by installing new purification systems.

If the results do not satisfy the standards, the hybrid system employing

activated sludge process and chemical treatment will be required.

If purification is difficult, it is processed as industrial waste disposal.

(Only diary and livestock wastewater can be recycled as liquid fertilizer.)

If the quality of processing water is slightly over the standards, it

can be discharged after diluted with ground water, rain water, or tap water

as long as it is within the 5th total volume control range.

|

|

Q6.What are the factors for estimating the cost of wastewater treatment

systems?

- We will provide appropriate quotations considering factors including actual

sites, lab tests, characteristics of wastewater, and your needs.

- Systems are available at low prices for light-level contamination and small-amount

wastewater treatment.

- Processing of highly concentrated wastewater containing persistent materials

(livestock, especially digestive fluid,) or chemical plant wastewater (polymeric

agent, chemicals) requires cost for COD, ammonia decomposition and etc.

- If you have any request for the removal method of organic materials (sedimentation,

filter, carbonization), please let us know. If pH, electric conductivity

and/or water quality fluctuate largely, additional facilities and systems

(e.g. adjustment tanks) to maintain the condition may be required.

- Additional facilities (system storage room, deodorizing equipment, etc)

will be required for sites with strong odor, or snowy or freezing area.

- Construction fee for installation (electric, water, and drainage facilities,

civil work) varies depending on actual site.

- Frequent meetings and making detailed drawings make the management cost

higher. (e.g. public projects)

- In some cases, hybrid systems (combined with biological treatment, chemical

feed) may be required, considering initial and running costs.

- Contact us with your requests. (e.g. auto error alarm [wireless/module

phone type], semi-auto operation to reduce operation and equipment cost)

|

|

Q7.Various purification methods

1)Differences between treatments of circulation water and industrial wastewater

- “General wastewater treatment” is defined herein as follows: Wastewater

including contaminants from factories and dairy & livestock farmers

is purified through a single-path processing from an intake port to output

port

- While wastewater containing contaminants is purified on the same day it

is generated, circulation water treatment improves the water quality over

time in the closed circulation systems, and the facility cost can be reduced.

2)Circulation water treatment

- Gross water capacity of circulation water means the total volume of water

used in the facility including water in facilities pipes, chillers, and

cooling tower.

- Silica scales are separated and removed by changing the characteristics

of circulation water through electro- and physicochemical processing without

using chemicals. It prevents generation of slime, breeding of legionella

and algae, and rust on pipes.

- Prevention of clogging caused by scale on pipes and heat exchanger improves

the heat exchange rate, reducing operating load and saving energy.

- It takes 7 to 15 days to produce effects after the circulation water treatment

system is installed.

- Periodical cleaning is required to remove contaminants separated from the

facilities and pipes during the initial stage after the installation.

- As a single cycle of contaminant removal process will be completed after

1 to 2 months after the installation, the system operation becomes stable.

Silica and scale in supply water for overblow are removed.

- Neglecting periodical maintenance, including the regular cleaning of the

circulation systems, insufficient design of heat load, and leaving clogged

heat exchangers for hot springs and bathes will result in the forced chemical

cleaning and sterilization. Regular cleaning and maintenance must be performed

as mass generation of filamentous fungi and legionella could happen in

worst case.

3)Water purification of lakes, ponds, dam lakes

- Since the closed water areas less than 100 tons (ponds, lakes, etc) take

a short purification time, the systems taking 1 to 15 day(s) to purify

water are used. Then, periodical purification is performed (semi-annual,

etc), depending on the condition of eutrophication.

- For purification of large closed water areas of 500 to 1000 tons (pond,

lakes, etc), it will take approximately 1 to 3 months. After one purification

cycle completes, it can be switched to smaller systems suitable to the

contamination level to prevent eutrophication. In this case, whole area

of the closed water system must be regularly circulated by water flow for

r purification.

- For purification of the closed water areas of 100,000 to 10,000,000 tons

(lake, dam lakes), it will take 1 to 3 years. Purification of a focused

area where contaminants are accumulated is effective. Considering resource

supply and natural environment (snow, freeze), detailed designs will be

required.

- ※As a common factor, load to purification becomes larger in the following

cases and in those cases, machine design and purification method should

be reconsidered: aquaculture in small closed water area with especially

small amount of water, a large number of fish in natural environment, heavy

accumulation of sludge, large amount of inflow water (naturally flown water,

hot spring, etc)

4)Industrial wastewater treatment (industrial/livestock wastewater)

- Determined amount of wastewater is treated in a single path process.

- We offer optimal procedures for various types of wastewater, including

hybrid facilities combining multiple technologies.

- Time and energy for separation and decomposition of contaminants in wastewater

treatment are measured, but they vary widely (from easy to process to time/energy

consuming ).

|

|

Q8.Necessity of environmental remediation

The two thirds of Earth’s surface are covered by water, but only 0.01%

of that is fresh water available for our daily life and for industrial

activities. As the pollution of the global environment continues, there

are growing concerns about the accumulation of water environmental pollutants,

and the polluted water continues to contaminate soils.

Immediate purification of the environment in the global scale is urgent

to prevent further contamination of the environment. Environmental purification

technology aiming for recycle-based society not causing secondary environmental

contamination is required.

For example, Kasumigaura is a typical closed water area and widely used

for farming and household water and so on. However, the quality of water

has not been improved since water quality standards had been set. Furthermore,

more strict regulation “the 5th volume control” has been issued for nitrogen

and phosphorus output standards, and “Act on Livestock Waste” has been

issued for dairy and livestock industry. With those backgrounds, achieving

the required water standards becomes a basic factor for local life and

advancement of industry.

|

|

Q9.Water Purification Methods

①Bioremediation (activated sludge process)

Characteristics: There are two methods. One method is to digest organic

materials by aerobic bacteria activated by aeration for nitrification.

Another method is to release nitrogen into air by denitrifying bacteria.

Pros:Generally and extensively used and effective to removal of BOD, nitrogen,

and SS. It is especially effective to small-amount purification.

Cons:Large installation area and long-term processing are required as well

as a large amount of energy for aeration. It is difficult to be adjusted

to the changes in COD, pigment degradation, and low-temperature (seasons).

②Dissolved air flotation (chemical injection)

Characteristics: Sludge is forcibly separated (precipitated/floated) with

use of coagulants or polymeric agents. This method is generally used in

industrial wastewater treatment as the advanced processing when the bioremediation

process is not sufficient. It is also used by itself.

Pros:Small installation area and short treatment time. Water purification

effects are expected in overall criteria.

Cons:More sludge is produced, and secondary environmental contamination

by the industrial waste disposal and chemicals are concerned.

③Heat treatment (incineration, evaporation, carbonization)

Characteristics: Heat treatment using fossil fuels or self-generated methane

gas

Pros:Sludge and water are definitely separated. Solids after carbonization

are porous and can be used for the assistant in the biological treatment.

Cons:There is a problem with the CO2 reduction measures in Kyoto Protocol,

and COD in evaporated moisture is not degraded.

④Oxidation treatment (A. Electrolysis/ B. Ozone gas/ C. Titanium dioxide)

A,Electrolysis

Characteristics: Although there had been few actual cases of electrolysis

wastewater treatment, more advanced purification technology has been developed

and gradually introduced to the market in these years.

Pros:Small installation area, energy-saving, and high level of purification

is available for wide range of environmental contaminants. Treatments which

have not been available previously, including decomposition of VOC, chlorine

compound, COD, and ammonia, separation of phosphorus, N-hexane, and SS

as well as decoloration in automatic operation.

Cons:In the case of industrial water, the facility cost could be a disadvantage

for a short-term large-volume treatment (500t/day or more).

B,Ozone gas

Characteristics: It has been gradually introduced to the market recently.

Pros:Small installation area, energy-saving, and high level of purification

is available for various environmental contaminants. Treatments which have

not been available previously, including mild decomposition of chlorine

compound, COD, and ammonia, as well as decoloration are available. Especially

it is effective in gas-phase purification and automatic operation is available.

Cons:Since ozone gas does not remain in water for a long time, it is not

suitable for in-water purification. In the case of industrial water, the

facility cost could be a disadvantage for a short-term large-volume treatment

(1t/day or more).

C,Titanium dioxide

Characteristics: Environmental contaminants, contacted to titanium dioxide

coating surface in gas-phase, react with the UV light and they are detoxified.

This method can be used as tile surface treatment (mixed with paint and

coated on walls).

Pros:High level of purification is available with little energy provided

by UV irradiation from the sunlight or UV lamps. Treatment which has not

been available previously, including decomposition of nitrogen compounds,

chlorine compound, COD, and ammonium is available.

Cons: Ultraviolet is required. Processing time is long even in the gas

phase, not suitable to the treatment in the liquid phase.

⑤Encapsulation, Storage in segregated facilities

Characteristics: Hard-to-degrade materials are encapsulated in containers

(such as glass) which do not elute the contents and controlled under segregated

facilities. PCB is a typical example of accumulation storage.

Pros:None

Cons:No solutions for purification of environmental pollutants

|

| Improving Water Quality by Electrolysis Treatment, Principle, Effects |

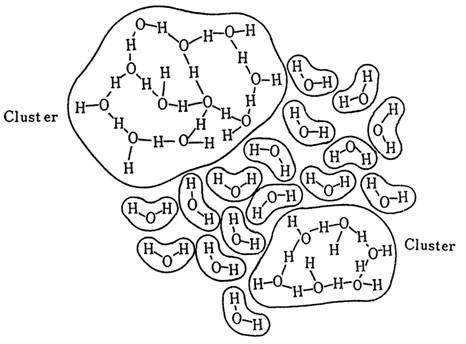

Q.What’s water cluster

|

Atom

|

A basic minimum unit of matter for an element, and varies, depending on

the types of the element.

|

|

Molecule

|

Aggregation of atoms

|

|

Water

|

Aggregation of a single oxygen atom and twp hydrogen atoms (H2O)

|

|

Water cluster

|

In a general theory, it is an aggregation of about seven water molecules

(as shown below).

|

|

|

|

Q.What is the conventional electrolysis?

In the case of direct current electrolysis, when the power is supplied

to the positive and negative electrode metals in a water solution, the

oxygen (O) is generated from the positive side and hydrogen (H) from the

negative side. The generated hydrogen forms air bubbles and goes into air

(gas-phase).

The positively charged ion components are drawn to the negative side, and

negatively charged ion components to the positive side. In a plating process,

a metal layer is grown by using this principle. This is the general theory

for the conventional electrolysis.

Pros:Complete separation of +/- ion components

Cons:Electrolysis in large water generates layers on the surface of the

electrodes, and the electrode contamination blocks electrical current.

As such, the sustainability of the process is low in long-term. Therefore,

it is mainly used in a plating process, and not other processes. (Physical

and periodical cleaning is required.)

|

|

Q.What is MICRO WATER SYSTEM?

The phenomenon illustrated in the following photos and drawings are induced.

1. In the newly developed patented electrolysis technology, active electrodes

are used as the positive electrodes (anode). Once electrical energy is

supplied, the electrodes are dissolved and flocs are formed through reaction

bonding as the positive and negative ion components are pulled in each

other. The generated oxygen has a characteristic to be dissolved into water

as DO (dissolved oxygen). On the other hand, non-active electrodes are

used as the negative electrodes (cathode). As hydrogen is removed from

the solution, hydrogen bonding is released in water clusters, and water

cluster is separated into micro clusters. Sludge including scale, silica,

iron, arsenic, heavy metals is separated and removed. (Currently no technology

is available to directly observe the water clusters. It is an interdisciplinary

theory.)

2. In the electrolysis reaction near the positive electrodes, electro‐oxidation

reaction occurs, inducing the strong oxidation. Micro Water System induces

the oxidative effects several tens of times more than ozone gas (widely

known for oxidation reaction and induces a similar phenomenon) with less

power consumption and at high efficiency when it is compared under the

same consumption energy.In this phenomenon, water contaminants including

COD, nitrogen, dioxin, PCB, VOC are efficiently decomposed. Furthermore,

the OH radical reaction is also induced, and the effect of oxidation is

maintained more than 1 hour in the solution.

(No flocs by ozone gas. Short effective time as ozone gas goes directly

to the gas-phase. etc.)

Sludge flocculated by micro bubbles of hydrogen gas generated from the

negative side (cathode) rapidly goes up. They are aggregated and completely

separated into the layers of purified water and sludge.

This phenomenon occurs as hydrogen gas is generated by mixture of sludge

and the hydrogen gas completely goes to the gas-phase by agitation, causing

the sludge to lose the capability to float. Then substances with heavy

specific gravities go down as they are pulled by gravity and settled down.

The settled down and separated environmental contaminants and purified

water maintain a complete saturated condition, and it does not return to

the water quality before the purification. Instead, it immediately recreates

the separation and decomposition state when it is mixed. In the case of

our sample, it maintains the separation and deposition state semi-permanently.

|

|

Q.How do algicidal treatment and sterilization treatment work?

Coliforms, legionella, O-157, salmonella, and algae (chlorophyll-a) are

killed by the oxidation described above. Furthermore, the system has unique

electrolysis charges, and the sterilizing effect is expected as they penetrate

the fungal cell membranes. Additionally, the mechanism is designed to function

in multiple ways and induce rapid pH fluctuations among liquid layers.

|

|

Q.What is the electrical cost?

Power 0.8Kw/h 24-hour operation

Example 1: Purification of pond/amenity water facilities (7 tons) : 200

yen/day

Example 2: Purification of circulation water (e.g. cooling tower, total

vol. 20t): 4,500 yen/month The consumption power is 1/10 of conventional

electrolysis systems.

(Running cost varies depending on purification conditions. Request us for

a quotation.)

|

|

Q.What about electrode contamination?

Even when the electrodes are contaminated, electrolysis is performed to

forcibly remove the contamination by using special electronic signal based

on the patented technology.

For high-viscosity materials such as dairy wastewater and clay, the solid

materials such as soil need to be dissolved into water to dilute it to

lower the viscosity.

There are two cases (out of 100) in which electrode contaminations occurred.

In these cases, the surfaces of the electrodes are cleaned once a day to

handle the situation. Although water quality analysis and chromatography

analysis were conducted, the cause of electrode contaminations has not

been identified.

|

|

Q.Why it is possible to purify persistent substances such as dairy wastewater?

IGADEN has developed high-power oxidation systems using electro-chemical

reactions for various types of persistent wastewaters to meet customer

needs (e.g. sterilization of large amount of water, decomposition of COD

or ammonia).

It is a new technology allowing highly efficient decomposition including

decoloration of dark-colored wastewater, COD decomposition with several

tens of thousands of PPm as well as livestock wastewater.

|

|

Q.It the system applicable to any type of wastewater?

No.

There are no same livestock/industrial wastewaters even if they are produced

at the same area and same process, influenced by the factors such as feedstuff

and groundwater, existing bacteria, or environmental temperature.

As water purification process contains intertwining factors and there are

phenomena and matters which have not been academically explained, the purification

lab test must be performed using actual wastewater for evaluation and verification

to meet customer needs.

|

|

Q.Are there any application examples and sales experiences?

You can view examples on our website: http://www.igaden.com

|

|

Q.Can I witness the demonstration test?

Please contact us in advance, and visit us with the wastewater.

We will demonstrate the purification lab test (5 to 10 minutes) and present

our technology.

|

|

Q.What are the evaluations from public organizations?

Experiences of collaborative researches with national, regional, local,

and public research organizations support the fine technology of the newly

developed electrolysis reaction.

1.Collaborative research with University of Tsukuba

Analysis of decomposition techniques for high-concentration COD and decomposition

of dioxin, collaborative project among industry, academia and government

2.Kasumigaura water purification project with Ministry of Education, Culture,

Sports, Science and Technology

Developing the efficient techniques for separating & collecting algae,

Research & development of effective purification method for lakes and

ponds

3.National Institute for Land and Infrastructure Management of Ministry

of Land, Infrastructure, Transport and Tourism

Empirical research project of dam lake purification in Japan (4 places,

5 dam lakes)

4.Collaborative research with the National Institute of Advanced Industrial

Science and Technology (AIST) of Ministry of Economy, Trade and Industry

Verification and research for sterilization of O-157, salmonella, staphylococcus

aureus, and legionella

Development of techniques for decomposition of VOC, and purification of

heavy metal contaminated soil, and others

5.Local regeneration consortium project commissioned by Hokkaido Bureau

of Economy, Trade and Industry

Know-how transfer project of seeds for technology to develop treatment

systems for highly persistent wastewater (e.g. livestock wastewater)

Participants: NARO Institute of Livestock and Grassland Science, The National

Institute of Advanced Industrial Science and Technology, Optoelectronics,

Division, and others

6.Industrial Technology Institute of Ibaraki Prefecture

Verification of the sterilization effect (legionella, coliforms)

7.IBRAKI Small and Medium Enterprise Promotion Public Corporation

Providing the technology for shifting to the chemical-free wastewater treatment

to the stone industry association

8.Sumitomo Metal Technology Inc.

Verification of the degradation efficiency for dioxin, PCB, and VOC

Verification of hard-biodegradable wastewater treatment

9.HITACHI MAXELL LTD.

Chromatography analysis of extracted silica and scales

|

|

Q.Are there any supports from public organizations?

There are supports from research organizations mentioned above and the

following organizations.

- The Science and Technology Promotion Foundation of Ibaraki

- Northern Advancement Center for Science and Technology (NOASTEC)

- Foundation for Advancement of International Science

- National Agriculture and Food Research Organization

- Industrial Technology Institute Of Ibaraki Prefecture

- Tsukuba forum aiming the recycling society

- Ibaraki Prefecture

- United Nations Industrial Development Organization (UNIDO)

- For more information, refer to Joint Study/Forum sites.

|

| Implementation of MICRO WATER SYSTEM |

Q.What are the requirements for the demonstration test?

- Bring in approximately 2 liters of wastewater for the test.

- Specify what kinds of substances are mixed in. Also specify the present

and target values for regulated items. (e.g. in ppm)Check the regulations

and limits, including your company’s regulations, local water contamination

limits, local government regulations and regulations and laws for effluent

to sewage, river, and oceans in advance.

- For plant wastewater: How much wastewater is produced? (daily, hourly)

How many hours of operations? Total volume of the wastewater from the plants,

types, systems, etc.

- What is the gross water capacity? How much water is stored in pipes and

pits in total?

- Inform us of pre-measured pH (especially strong acid, alkali water) as

they are dangerous to transfer.

- Do not bring in any wastewater containing dioxin, hexavalent chromium,

cyan, arsenic, and undiluted chemicals which are legally prohibited to

move or with bad odor.

- Some wastewater characteristics may require prior examination.

|

|

Q.What if pH is abnormally high?

Since the electrode plates will melt in extremely strong acid, the purification

treatment is reviewed after pH is adjusted.

|

|

Q.What is required for quotations?

Other than the above:

- Current processing procedures

- Specific purification level (e.g. values of SS, BOD, COD, PH, Ni, P, N-hexane,

VOC, heavy metal, color, odor, and other materials)

- Budget

- For official quotations, detailed purification lab test (comparison before

and after processing water) and water quality check (measurement certification)

will be required at cost.

- Review conditioned installation sites.

|

|

Q. How much purification is possible?

Refer to the data before and after purification on our website.

|

|

Q.Are there any standard systems?

We provide the standard systems for cooling tower circulation water treatment

as well as livestock/dairy wastewater treatment.

Standard baths could be offered at reasonable prices; however, systems

for factory wastewater treatment are all customized for each case to meet

actual conditions and needs.

Visit our website for application examples.

|

|

Q.Is the on-site test available?

Movable samples such as for the lab test can be tested, but on-site test

similar to an actual operation including transportation by a truck will

require a quotation and test will be performed with charge.

|

|

Q.What is the system flow?

We will provide the optimum purification system flow suitable for each

site.

|

|

Q.Is only electrolysis available?

Basically, we offer chemical-free electrolysis systems. However, we also

propose purification system using chemicals (e.g. non-organic water adjusters)

if it is judged appropriate after the condition of wastewater and electrolysis

efficiency are tested and the reduction in the initial cost and running

cost are reviewed. For the chemicals to be used, the safety sheet is provided

considering the environment aiming for a recycling society.

|

|

Q.Can the Micro Water System be used with existing systems?

When the use with conventional active sludge processing, chemical treatment,

or film processing saves the implementation cost, the electrolysis system

is designed as an additional system.

|

| Electrolysis Technology Comparison Chart |

| Item |

Direct Current Water Treatment System |

Alternative Current Water Treatment System |

MICRO WATER SYSTEM |

| ph |

Acid /alkali separation |

No change |

No change (slight shift to alkali) |

| Sludge |

Solidified |

Large grains |

Separated into flocs |

| Floc |

Solidified |

Large grains |

No change over time |

| Grain size |

Large grains only |

Large grains only |

Micro-small grains |

| Scale condition |

Electrode plate is completely insulated. |

Electrode plate is completely insulated. |

Cleaned by self-cleaning |

| Electrode contamination |

Electrode plates are completely insulated. |

Electrode plates are completely insulated. |

Cleaned by self-cleaning |

| Maintenance of electrode |

Required daily ®ularly. |

Required daily ®ularly. |

Basically, maintenance-free |

| Electrical shock |

Blown off |

Pulled in |

Only around electrodes |

| Difficulty of voltage variable |

High-voltage and continuous change from 0V |

High-voltage and continuous change from 0V |

Fixed at the optimum value for water purification by the electric circuit |

| Power consumption/Processing efficiency |

Sum of voltage*current |

Sum of voltage*current |

Operates with the efficiency 1.4 times better than general commercial voltage |

| General processing capability |

Suitable for small-volume processing |

Suitable for small-volume processing |

10 times faster than conventional processing speed |

| Phosphorus removal |

△ |

△ |

◎ |

| Nitrogen removal |

△ |

△ |

◎ |

| Sterilization |

? |

? |

◎ |

| Removal of scale |

? |

○ |

◎ |

| Iron rust removal |

? |

○ |

◎ |

| Algicidal treatment |

? |

○ |

◎ |

| Dioxin removal |

? |

? |

◎ |

| Heavy metal, mineral removal |

? |

○ |

◎ |

| Oil separation |

△ |

△ |

◎ |

| System cost for processing 100t |

High |

High |

Reasonable |

| Applicable system |

Alkaline ionized water(Function water) |

For compact size due to additional values. |

Applicable to mass processing. |

|

Legend:△Possible by conditions ○Slightly effective ◎Good |

|

| Water Treatment Technology Comparison Chart |

| Item |

Bacteria active sludge removal |

Floatation and chemical treatment |

MICRO WATER SYSTEM |

| Amount of scum |

30% |

12% |

1% |

| Installation area |

500㎡ |

100㎡ |

30㎡ |

| New construction |

On-site construction, long-term |

Installed after the plant is completed. |

Installed after the plant is completed. |

| Adding system for increase in production |

Difficult

(Due to space) |

Easy

(Possible, considering total condition) |

Easy

(Can be partially added.) |

| Load fluctuations |

Fluctuates over seasons |

Stable |

Stable |

| Obtaining treatment quality |

Fluctuates over seasons |

Stable |

Stable |

Running cost (comparison of lake purifications)

(per 1 ton) |

250 yen +labor fee |

118 yen |

87 yen |

Maintenance control

(Need for certified operators) |

Frequent

(Required) |

Automatic

(Not required) |

Automatic

(Not required) |

| System startup time |

Depends on activation of bacteria (long-term) |

◎ |

◎ |

| Deodorant effect |

× |

× |

◎ |

| Sterilization, Algicidal treatment |

× |

× |

◎ |

| Fresh water treatment |

◎ |

◎ |

◎ |

| Seawater treatment (saline water) |

× |

◎ |

◎ |

| Possible generation of trihalomethane |

Yes |

Yes |

No |

| Chlorine compound decomposition |

× |

× |

◎ |

| Water quality for fish survival |

× |

× |

◎ |

| Water temperature |

Restrictions for bacteria survival |

◎ |

◎ |

| pH |

× |

◎ |

◎ |

| Changes in pH after treatment |

No |

Yes |

Yes |

| SS Improvement |

Emulsification & removal are not available. |

Slight emulsification |

◎ |

| Low BOD |

◎ |

◎ |

◎ |

| Low COD |

× |

△ |

◎ |

| Nitrogen decomposition |

× |

× |

◎ |

| Phosphorus collection |

Unavailable to remove |

Mixed with chemical |

Possible to collect |

| Scum fertilizer |

Available depending on the contents. |

Not available as chemicals are mixed in. |

Available |

| N-hexane extract separation & collection |

50% |

80% |

99% |

|

Legend: ×Not available △ Available by condition ◎ Good

Based on 100t/D (standard system) |

|

|

|

|

| Copyright (C) IGADEN CO.,LTD. All Rights Reserved. |

|