Chemical-free Cooling Tower Circulation

Water Treatment System

|

Characteristics

- Chemical-free water treatment for cooling towers

- Scale removal from circulation water

- Scale removal from pipes and facilities

- Less load to the pumps, save the power

- Prevention of high-pressure cut

- COD measures for wastewater

- Red-rust removal and prevention

- Algae prevention

- Water-bloom prevention

- Slime prevention

- Significant running cost reduction

- Less regular maintenance

- Water conservation

|

|

|

|

|

|

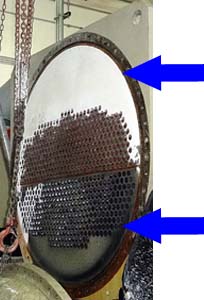

The heat exchanger is clogged by silica scale even when chemical treatment

is performed. (Upper area: Before cleaning)

The white area is where scales are attached, and the scales completelyclog

the heat exchange pipes. |

After chemical cleaning

(Lower area: After chemical cleaning)

Black area: heat exchanger pipes |

|

|

| Purification of circulation water by catalytic reaction |

| The scale removal effect can be observed shortly (approx. 3 hours) after

installation of the system by innovative patented technology, and the energy

and space can be saved. |

|

As environmental pollution escalates, water purification technologies that

emphasize global environment conservation while seeking coexistence with

a natural environment and a recycling-based society are desired. We offer

a chemical-free environmental contaminant elimination system (patented)

that uses an electro-physicochemical reaction. It contributes to conservation

planning for water, space, and electric power, as well as for reduction

of CO2.

Our system has been adopted in the “Kasumigaura water purification project”

(a project for developing technologies to purify eutrophicated lakes by

the Ministry of Education, Culture, Sports, Science, and Technology), “Development

of purification system for hard-to-process wastewater such as wastewater

from dairy parlors” (by the Ministry of Economy, Trade, and Industry),

and the “Purification project for dam lakes” (by the Ministry of Land,

Infrastructure, Transport, and Tourism), receiving recognition for its

efficient.

|

|

As the temperature in the cooling tower rises to a degree optimal for bacteria

growth, scale within the piping accumulates due to algae, bacteria, and

concentrated circulation water, causing blockage in the heat exchanger.

This in turn leads to issues such as decrease in efficiency in heat exchange

and growth of legionella nesting in the scale inside the piping. (Mold

fungi appear if regular cleaning is not well maintained.)

Chemical products have traditionally been used to deal with these issues.

However, as the circulation water is evaporated and concentrated by the

heat of evaporation, chemical component discharge (COD) during automatic

overblow (blowdown) has been a recent concern. Thus, the maintenance cost

is high.

The chemical-free water treatment system, “MICRO WATER SYSTEM” (patented)

reduces maintenance, and operates while conserving energy at low costs.

It can also separate and collect the scale in the circulation water, control

saprophytic contamination, kill algae, and conserve water. Especially,

this system has consistently been delivered to many ISO 14001 certified

companies, gathering attention.

Alternative water treatment for chemicals Chemical-free cooling tower circulation

water treatment system

|

|

Chemical-free Cooling Tower Circulation Water Treatment System

|

|

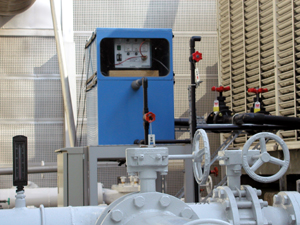

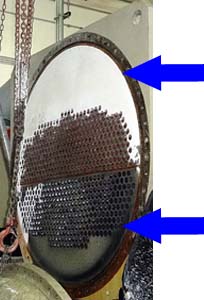

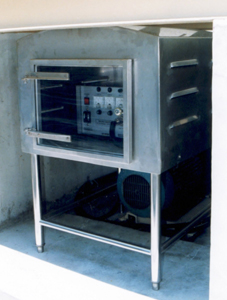

- Cooling Tower Circulation Water Treatment System

- 1 unit

- In Japan

- Scale removal

- Chemical-free

|

|

|

|

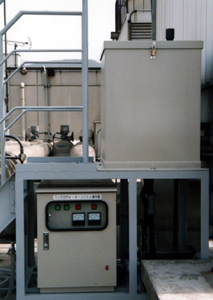

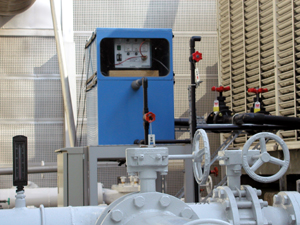

- Cooling Tower Circulation Water Treatment System

- Total circulating water: 15 tons

- 2 units

- In Japan

- Changed from the chemical injection to chemical-free electrolysis water

treatment

- Algicidal treatment

- Scale removal

Provided by JTEC Corporation |

|

|

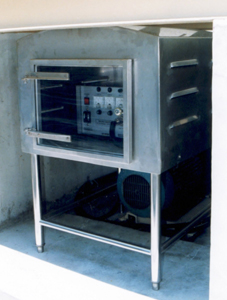

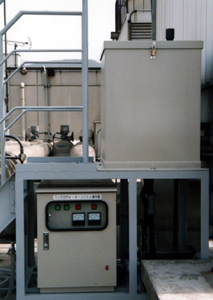

- Cooling Tower Circulation Water Treatment System

- Total circulating water: 18 tons

- 3 units

- Home appliance manufacturer in Indonesia

- Changed from the chemical injection to chemical-free electrolysis water

treatment (Cost-savings)

- Algicidal treatment

- Scale removal

|

|

|

|

- Cooling Tower Circulation Water Treatment System

- Total circulating water: 22 tons

- 1 unit

- Home appliance manufacturer in Singapore

- Changed from the chemical injection to chemical-free electrolysis water

treatment

- Algicidal treatment

- Scale removal

- No bacteria

Provided by Everfeed Technology Pte Ltd

|

|

|

|

- Cooling Tower Circulation Water Treatment System

- Total circulating water: 15 tons x 2 units

- 2 units

- In Japan

- New installation

- Chemical-free treatment

- Scale removal in makeup water

- Algae growth prevention

|

|

|

|

- Cooling Tower Circulation Water Treatment System

- 1 unit

- In Japan

|

|

|

- Cooling Tower Circulation Water Treatment System

- 1 unit

- In Japan

- Chemical-free treatment

- Scale removal

- Algae growth prevention

|

|

|

- Cooling Tower Circulation Water Treatment System

- 2 units

- In Japan

- Scale removal

|

|

|

- Cooling Tower Circulation Water Treatment System

- 1 unit

- In Japan

- Scale removal

|

|

|

- Cooling Tower Circulation Water Treatment System

- 1 unit

- In Japan

- Scale removal

|

|

|

- Cooling Tower Circulation Water Treatment System

- 1 unit

- Total circulating water: 11 tons

- In Japan

- Changed from the chemical injection to chemical-free electrolysis water

treatment

- Scale removal

- Algae growth prevention

|

|

|

- Cooling Tower Circulation Water Treatment System

- 1 unit

- In Japan

- No chemical

- Scale removal

|

|

|

- Cooling Tower Circulation Water Treatment System

- 1 unit

- In Japan

- Scale removal

|

|

|

- Cooling Tower Circulation Water Treatment System

- 1 unit

- In japan

- No chemical

- Scale removal from pipes

- Algae growth prevention

|

|

|

- Cooling Tower Circulation Water Treatment System

- 2 units

- In Japan

- Scale removal

|

|

| Cooling Tower Circulation Water Treatment System (Before and After Installation) |

Before (Chemical Treatment) |

1 Month after Installation (Non-chemical) |

Comparison of Images

- Forms are no longer generated

- Slimes (bacteria) on pipes and inner walls are prevented.

- Algae (algae, water-bloom) inside of the cooling tower are prevented.

Other

- Calcium and silica scales are collected using the cooling tower circulation

water treatment system.

- Scale on outer walls of the cooling tower is eliminated.

- Growth of algae and bacteria on outer walls is prevented.

|

NOTE: Load to the system depends on the surrounding environment. For details,

please contact us.

|

|

Cooling Tower Circulation Water Electrolytic Sterilization Test

(Cooling tower water from Japanese Home Appliance Manufacturer in Indonesia) |

|

|

MICRO WATER SYSTEM |

Chemical Water Treatment |

| Common Bacteria(CFU/ml) |

1.3×102 |

2.7×104 |

| Coliforms(CFU/ml) |

|

| Consumables, Maintenance and Inspection |

- Maintenance and Inspection: The system operates automatically, but regular

inspection is required.

- Consumables: The electrode plates need to be replaced every six months

or one year.

- Applicable to the electrical conductivity of 400-1200 μS/Cm. The automatic

blow is set to the highest possible value.

|

|

Patent No US6,706,168B2

特許第3635349号

特許第6343760号 |

|

|

|

| Copyright (C) IGADEN CO.,LTD. All Rights Reserved. |

|

| Contact idj@igaden.com |

|